-

Material Selection for Extreme Conditions

The performance of Multi-Port Selector Valves in high-pressure and high-temperature environments begins with the careful selection of materials. Valve bodies are typically constructed from stainless steel, carbon steel, brass, or high-performance alloys that are capable of withstanding extreme pressures and temperatures without warping, cracking, or corroding. Internal components, including seats, spools, and seals, are often made from high-temperature resistant polymers such as PTFE, Viton, or other engineered elastomers. These materials provide mechanical strength, thermal stability, and chemical compatibility, ensuring that the valve maintains both integrity and sealing performance over extended periods of operation. The correct material selection is essential for preventing failures, leakage, or deformation under demanding conditions. -

Robust Structural Design

Valves intended for high-pressure and high-temperature applications feature reinforced structural designs to resist deformation or mechanical failure. This includes thicker valve walls, strengthened flanges, and precision-engineered internal flow channels that distribute pressure evenly throughout valve body. Seats and sealing surfaces are manufactured with tight tolerances to prevent leaks even under thermal expansion or high-velocity fluid flow. By combining structural rigidity with precision engineering, the valve can maintain consistent performance and shape, ensuring reliable operation over long-term industrial use. Such design considerations are critical for maintaining safe and uninterrupted fluid control in demanding systems. -

Temperature-Compensated Sealing Systems

Sealing systems play pivotal role in handling extreme pressures and temperatures. Multi-Port Selector Valves often use temperature-compensated seals designed to expand or contract with thermal fluctuations while maintaining a secure seal between ports. High-performance polymers like PTFE or graphite-based seals retain elasticity at elevated temperatures, while some metal-reinforced seals prevent extrusion under high-pressure conditions. These advanced sealing systems minimize cross-port leakage and maintain system integrity, allowing the valve to operate effectively in high-temperature pipelines or pressurized systems without frequent maintenance or adjustment. -

Pressure Regulation and Flow Control

The internal design of Multi-Port Selector Valves ensures that extreme pressures do not compromise performance. Flow channels are precisely engineered to manage pressure distribution and reduce turbulence, preventing localized stress concentrations that could lead to cracks or mechanical failure. For high-temperature fluids, careful control of flow paths mitigates thermal gradients that could otherwise cause uneven expansion or stress on valve components. This design ensures that the valve continues to provide smooth and precise switching between ports while maintaining system integrity, even when exposed to rapidly changing or extreme operational conditions. -

Advanced Actuation Mechanisms

High-pressure or high-temperature fluids can increase the resistance felt when switching ports manually. To address this, Multi-Port Selector Valves often incorporate pneumatic, hydraulic, or electric actuators. These actuation systems are engineered to deliver consistent torque and precise movement of the valve rotor or spool, enabling smooth switching even under extreme conditions. Advanced actuation prevents sticking, misalignment, or incomplete port closure, ensuring reliable operation while protecting the valve’s internal components from mechanical stress or wear. Proper actuation also allows for integration with automated control systems, enhancing operational efficiency.

- Home

- Products

- Specialty Valves

- Cryogenic Valves

- Ultra High Pressure Angle Type Valves

- Disc Rise Plunger Valves for Bottom Discharging

- Inclined-Stem Tank Bottom Ball Valves

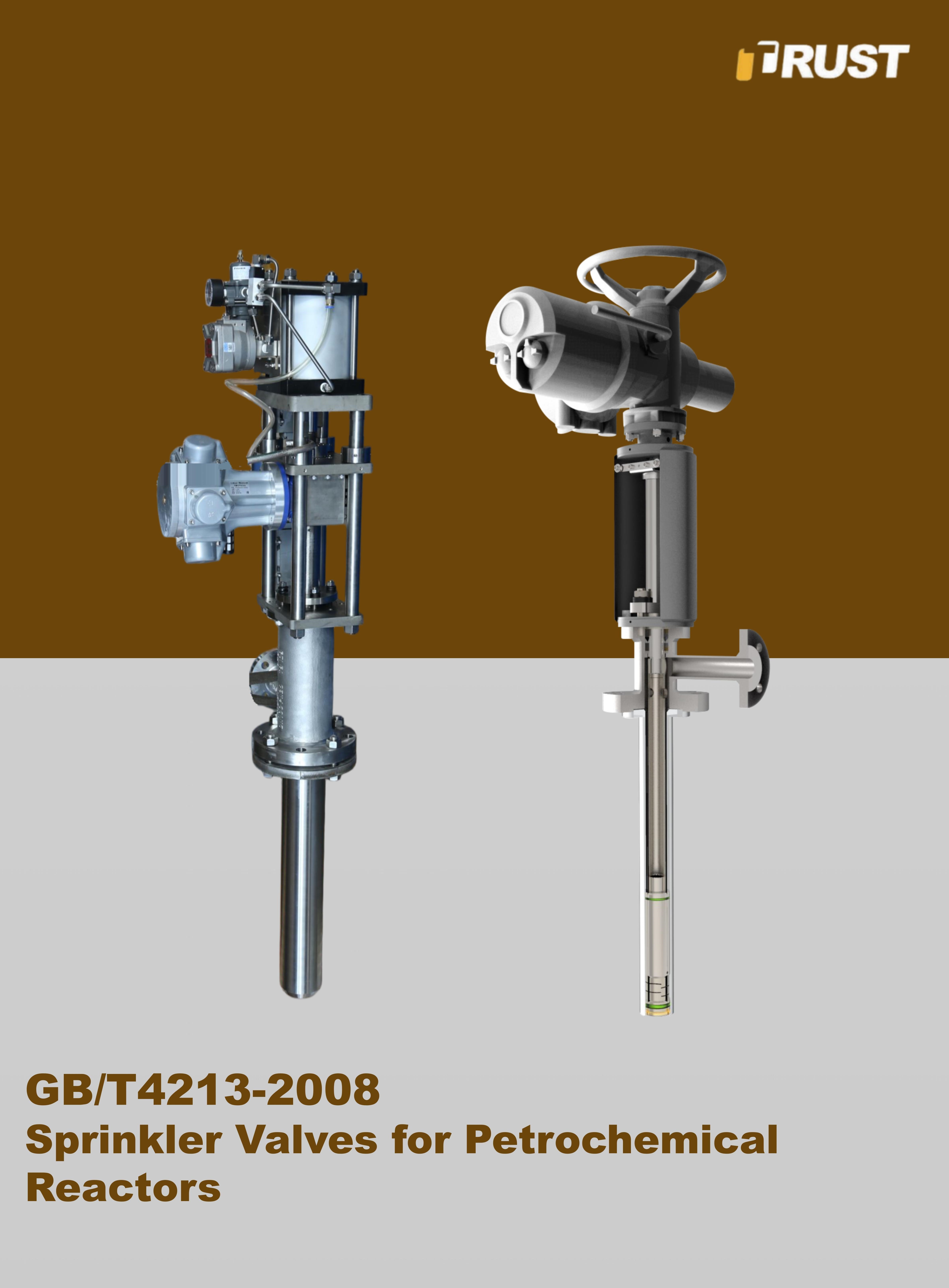

- Sprinkler Valves for Petrochemical Reactors

- Double Block and Bleed (DBB) Valves

- Pig Valves for Oil & Gas Pipelines

- LNG Loading Arm Emergency Release Coupling (ERC) Valves

- Multi-Port Selector Valves

- Axial Flow Shutoff & Control Valve

- Rising Stem Ball Valves

- Quarter Turn Valves

- Gate/Globe/Check Valves

- Specialty Valves

- Industries

- Engineering

- Quality

- News

- Resources

- Contact

English

English русский

русский Français

Français 中文简体

中文简体 Português

Português Español

Español italiano

italiano عربى

عربى فارسی

فارسی

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province  +86-515-87398111

+86-515-87398111  office@trustvalve.com

office@trustvalve.com