-

Inclined-Stem Design for Complete Drainage: The defining feature of the Inclined-Stem Tank Bottom Ball Valve is the angled stem, which positions the valve mechanism away from the centerline of the outlet. This design allows the ball to fully retract from the tank bottom when opened, effectively eliminating dead zones where liquid might otherwise remain. Complete drainage is especially critical when handling hazardous, corrosive, or viscous fluids, as residual material can continue to react with the tank interior, accelerate corrosion, or pose safety hazards during maintenance. By enabling the entire tank contents to flow freely toward the outlet, the inclined stem ensures that operators can safely drain tanks with minimal risk of leftover residue, reducing the potential for contamination, chemical reactions, or unsafe exposure during cleaning procedures.

-

Full-Port Ball Mechanism: The Inclined-Stem Tank Bottom Ball Valve typically employs a full-port ball design, meaning the internal bore of the valve matches or slightly exceeds the tank outlet diameter. This full-bore configuration minimizes restrictions and allows liquids to pass freely, ensuring rapid and complete drainage even for thick, particulate-laden, or high-viscosity fluids. For hazardous or corrosive liquids, the full-port design also reduces turbulence and prevents fluid stagnation around the ball or seat, which could compromise sealing or lead to chemical degradation over time. By maintaining an unobstructed flow path, this valve type not only improves drainage efficiency but also minimizes operational risks in industrial processes involving dangerous or reactive chemicals.

-

Material and Seal Selection for Hazardous Liquids: The safe handling of aggressive chemicals or corrosive fluids requires that the Inclined-Stem Tank Bottom Ball Valve be constructed from corrosion-resistant materials, such as stainless steel (304 or 316), Hastelloy, titanium, or other high-performance alloys. In addition, the seats and seals are made from chemically compatible materials such as PTFE, PEEK, or Viton, which resist degradation from exposure to acids, bases, or solvents. These materials ensure that even during complete drainage, the valve body, stem, and sealing surfaces remain intact and leak-free. By combining robust materials with precise engineering tolerances, the valve provides reliable containment of hazardous liquids, safeguarding both personnel and the surrounding environment.

-

Smooth Flow Path and Sediment Management: The internal geometry of the Inclined-Stem Tank Bottom Ball Valve is optimized for efficient drainage and minimal dead space. The angled design, combined with the smooth, polished surfaces of the ball and valve body, allows liquids to flow unimpeded from the tank bottom to the outlet. This reduces the accumulation of sediment, slurries, or particulate matter that could compromise flow or damage the valve over time. In addition, many designs incorporate gently contoured seats or self-cleaning features to further minimize residue buildup. This is particularly important in chemical, pharmaceutical, or food-grade applications, where thorough drainage is essential for maintaining product quality, safety, and compliance with hygiene or environmental regulations.

-

Safe Operation and Maintenance: By ensuring complete and efficient drainage, the Inclined-Stem Tank Bottom Ball Valve minimizes the need for manual intervention, reducing the risk of operator exposure to hazardous or corrosive liquids. This design also facilitates safe cleaning and maintenance procedures, as the tank can be emptied fully before inspection, repair, or disassembly. Coupled with corrosion-resistant materials, robust sealing systems, and full-port design, the valve ensures safe containment and controlled discharge of fluids, even under high-pressure or chemically aggressive conditions. For industrial operators, this translates into enhanced safety, improved process reliability, and compliance with environmental and workplace safety standards, all while maintaining operational efficiency in critical fluid-handling applications.

- Home

- Products

- Specialty Valves

- Cryogenic Valves

- Ultra High Pressure Angle Type Valves

- Disc Rise Plunger Valves for Bottom Discharging

- Inclined-Stem Tank Bottom Ball Valves

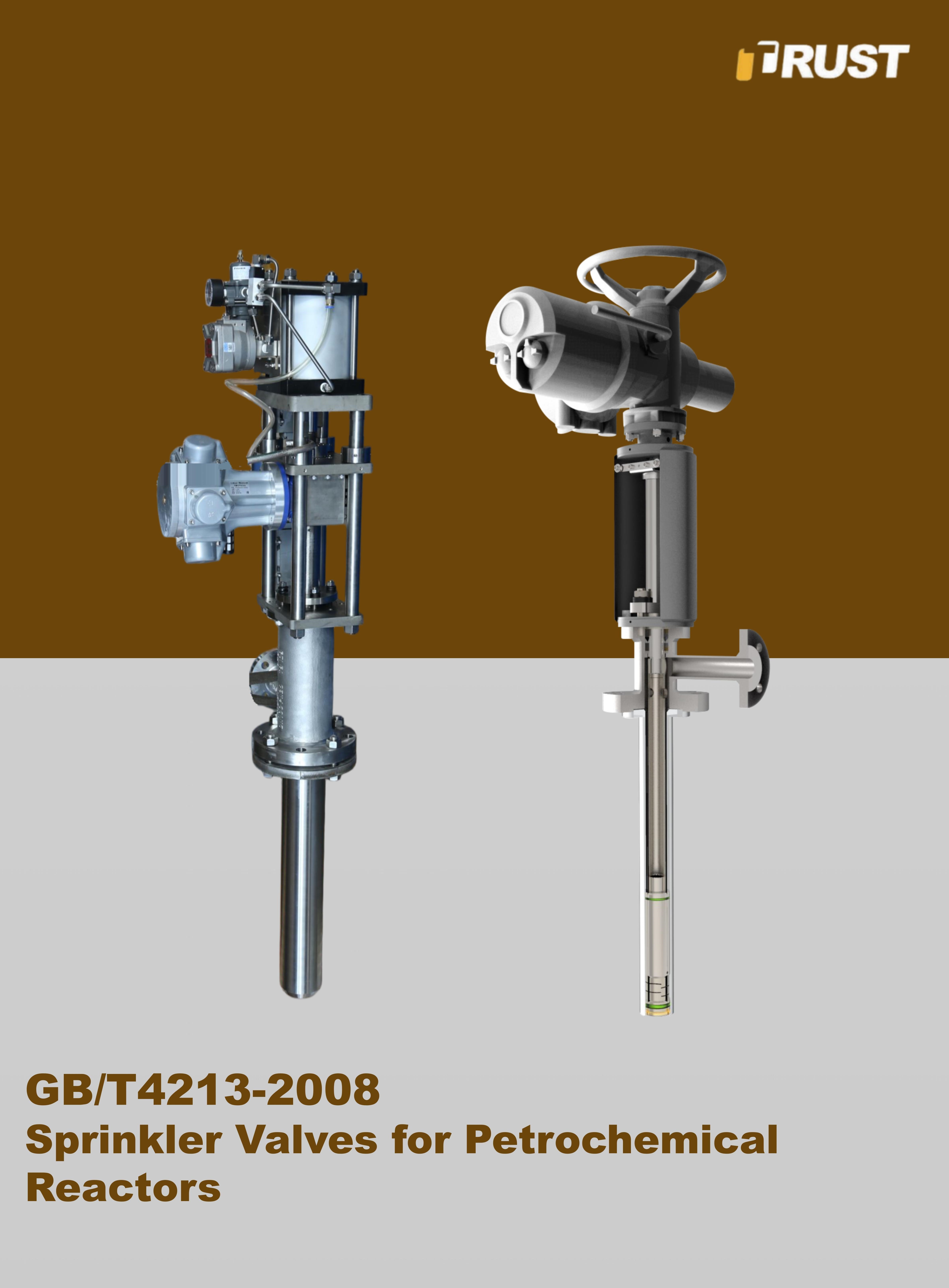

- Sprinkler Valves for Petrochemical Reactors

- Double Block and Bleed (DBB) Valves

- Pig Valves for Oil & Gas Pipelines

- LNG Loading Arm Emergency Release Coupling (ERC) Valves

- Multi-Port Selector Valves

- Axial Flow Shutoff & Control Valve

- Rising Stem Ball Valves

- Quarter Turn Valves

- Gate/Globe/Check Valves

- Specialty Valves

- Industries

- Engineering

- Quality

- News

- Resources

- Contact

English

English русский

русский Français

Français 中文简体

中文简体 Português

Português Español

Español italiano

italiano عربى

عربى فارسی

فارسی

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province  +86-515-87398111

+86-515-87398111  office@trustvalve.com

office@trustvalve.com