Why are Axial Flow Check Valves the Ultimate Solution for Preventing Surge and Maximizing Flow Efficiency?

In the critical domains of fluid management, spanning Oil and Gas Transmission, specialized Petrochemicals processing, and high efficiency Gas Compression Stations, the need for absolute control over backflow is constant. Axial Flow Check Valves are distinct from older, less efficient non return valves, such as swing or lift check valve designs, because they provide a highly efficient, demonstrably non slamming closure mechanism. These valves are precisely engineered to manage high velocity fluid movement and extreme pressure environments, ensuring that any flow interruption is rapid, exceptionally smooth, and critically, does not induce destructive pressure transients known as water hammer. The superior aerodynamic design and fully inline operation of Axial Flow Check Valves make them essential for protecting costly rotating equipment like pumps and compressors while simultaneously maximizing the entire system’s energy efficiency.

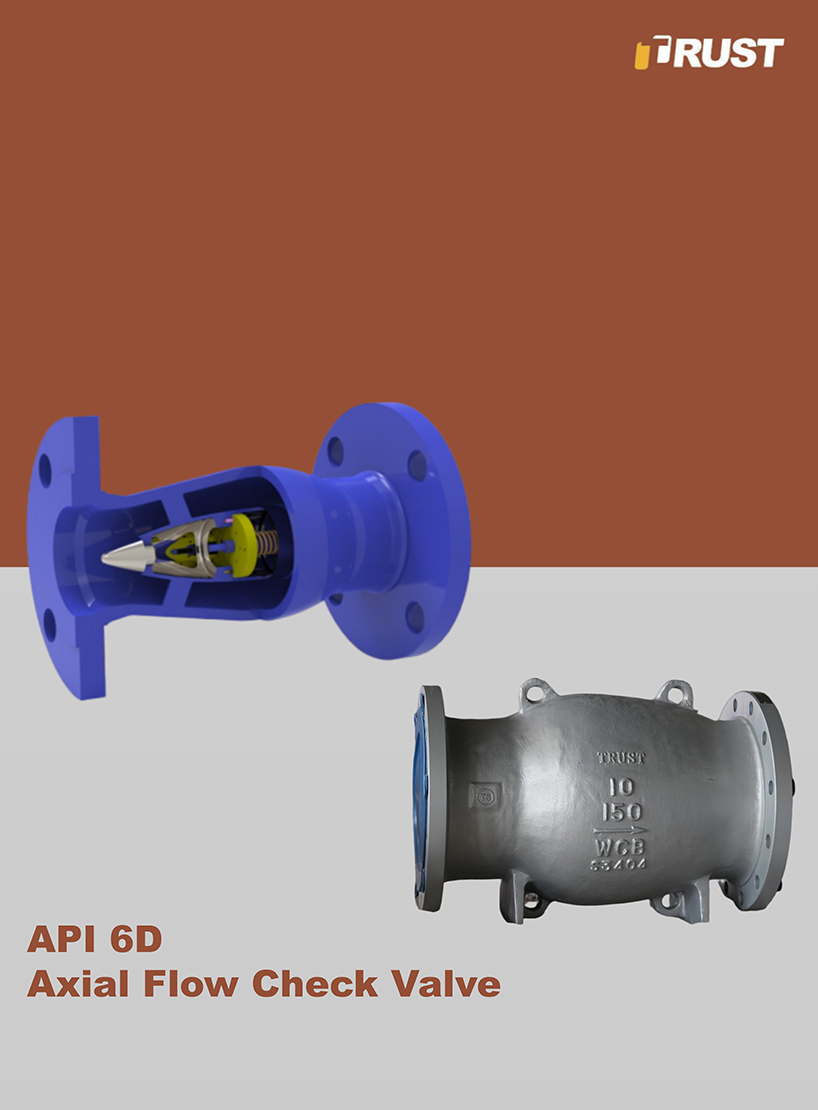

Product Engineering for Non Slam Operation and Hydraulic Excellence

The definitive advantages of Axial Flow Check Valves originate from their unique internal geometry and specialized operational kinematics. These elements are specifically integrated into the design to overcome the inherent dynamic limitations and high wear rates associated with traditional check valve designs.

The core operational benefit is the non slam and rapid response design, a feature central to system safety. This advanced fluid dynamic engineering ensures that the valve's internal element, which is typically a spring loaded disc, responds instantaneously to any deceleration of the forward flow. The moving disc within the Axial Flow Check Valve travels only a minimal distance along the central axis and closes precisely at the exact moment of flow reversal. This swift and meticulously controlled axial action prevents the reverse flow’s destructive inertia from building up kinetic energy, which is the singular primary cause of destructive water hammer. This crucial capability is non negotiable for pump stations and complex pipeline networks where sudden power outages, emergency shutdowns, or valve closures frequently occur, providing essential protection for pumps and compressors from sudden and severe pressure surges and component fatigue.

A significant, quantifiable hydraulic benefit is the exceptional low pressure drop and corresponding high flow efficiency. Because the flow path through the valve is straight, or strictly axial, the process fluid passes through with the least possible deviation or obstruction. This straight line flow geometry means that the Axial Flow Check Valves introduce very little fluid turbulence and minimal resistance when they are in the fully open position. This critical minimization of kinetic energy loss translates directly into high operational efficiency and results in substantial energy savings across extensive pipeline infrastructure. For operators responsible for managing vast networks, such as Subsea Pipelines or long distance gas transmission routes, where compounding small gains in efficiency yield massive reductions in pumping power and associated operational costs, this hydraulic feature is tremendously valued.

The compact and fully inline installation feature offers distinct logistical and structural advantages over bulkier, traditional designs. The streamlined, cylindrical profile of the Axial Flow Check Valve allows the unit to be installed directly into the pipeline without requiring additional clearance space for disc movement or complex external structural mechanisms. This inherent design capability enables reduced installation space and significantly simplified pipe support structures. This benefit is particularly valuable in confined or space constrained environments such as topside modules on Offshore Platforms or within highly dense processing units in a modern Petrochemical plant. The ease of integration simplifies the overall system design, reduces material costs, and diminishes the overall construction footprint.

High integrity sealing and robust pressure capacity are guaranteed through robust construction methodologies and precision manufacturing standards. Axial Flow Check Valves are consistently built to manage the immense pressure classes typical of high performance systems, with ratings often extending well beyond standard industrial requirements. The internal spring loaded disc mechanism ensures that high pressure is maintained effectively, providing high integrity sealing against backflow. This robust construction, which often utilizes forged steel bodies for maximum strength, confirms the long service life of the valve, even under conditions of continuous high pressure service within Power Generation facilities where uptime is essential. The spring element itself is precisely engineered to provide the optimal balance between opening pressure and quick closure performance, ensuring reliable operation over thousands of cycles without compromising the non slam functionality.

What Technical Specifications and Product Range Define the Deployment Versatility of Axial Flow Check Valves?

The successful deployment of Axial Flow Check Valves in critical infrastructure is contingent upon rigorous adherence to technical specifications, advanced material science, and specialized testing protocols. The construction of these valves must meet the most stringent global standards to ensure long term performance in extreme service. This section details the product types and technical requirements that govern their application.

Product Range and Dimensional Versatility

The specific Size Range for these critical components typically spans from Nominal Pipe Size one inch up to forty eight inches, accommodating everything from small utility lines within a refinery to the largest transmission mains carrying bulk volumes of natural gas. This vast dimensional scope allows the Axial Flow Check Valve to be applied across the entire spectrum of fluid infrastructure, ensuring non slam protection is available at every point. They are engineered to handle extreme pressure requirements, with Pressure Classes often ranging from six hundred up to four thousand five hundred, covering all supercritical and ultra high pressure applications up to Pressure Nominal seven hundred sixty. This immense versatility in size and pressure rating allows the Axial Flow Check Valve to be technically adaptable to diverse and complex operational requirements across the energy sector, including specialized applications in Liquefied Natural Gas terminals and high pressure gas systems.

The Temperature Range that Axial Flow Check Valves are built to endure is extensive, designed to operate reliably across a vast thermal spectrum. The careful selection of body and trim materials ensures continuous performance from severe cryogenic conditions, such as those found in Liquefied Natural Gas terminals, up to ultra high temperatures exceeding five hundred degrees Celsius, which are common in Power Generation steam lines. This wide thermal flexibility requires precise metallurgical control and specialized heat treatment protocols during manufacturing to prevent brittle fracture at low temperatures or creep failure at high temperatures, ensuring the spring mechanism and disc function flawlessly across this entire range.

End connections are designed for high integrity and permanent integration into the pipeline structure. Common connections include Flanged connections conforming to American Society of Mechanical Engineers B sixteen point five, Butt Weld connections per American Society of Mechanical Engineers B sixteen point two five, and Ring Type Joint connections. The precision machining of these connections is essential to ensure seamless mechanical and pressure boundary integration into any system, regardless of the pipeline material or joining method employed. The choice of connection type dictates the required wall thickness and material grade to maintain integrity across the valve body.

Material Science and Compliance Requirements

Construction Materials are carefully and scientifically selected to withstand specific forms of corrosion, temperature cycling, and mechanical stress. These include robust grades like Carbon Steel for general service, various Alloy Steel grades, such as chrome molybdenum variations, for high temperature service, various Stainless Steel grades, and high strength, highly corrosion resistant alloys such as Duplex and Super Duplex for sour gas or harsh chemical environments. The meticulous choice of material ensures the longevity, absolute structural integrity, and safe operation of the Axial Flow Check Valve in every demanding application environment. Trim components, such as the disc and seat, are often hardened using treatments or overlay materials like Stellite to resist erosion from high velocity flow, preserving the valve's sealing life.

The performance and reliability of Axial Flow Check Valves are confirmed through comprehensive testing required by international standards. This rigorous process includes hydrostatic shell testing to verify body integrity under maximum pressure, and seat leakage testing to confirm the disc and spring mechanism provide adequate non return sealing. For pipeline applications, the valve must be compliant with standards such as American Petroleum Institute six D, which mandates specific design criteria and performance testing to ensure reliability in mainline service. Further safety confirmation often requires fire safe testing, verifying that the valve’s pressure boundary remains intact during external fire events, which is critical for highly volatile media within Petrochemicals and Oil and Gas facilities. This commitment to testing ensures the Axial Flow Check Valve meets the highest global standards for safety and endurance.

Specialized Service Adaptations and Cryogenic Performance

The inherent low turbulence and rapid closure mechanism of the Axial Flow Check Valve are uniquely advantageous in highly specialized service environments. For instance, in Liquefied Natural Gas terminals, where temperatures drop to negative one hundred sixty two degrees Celsius, the minimal internal components and straight through flow path reduce potential areas for thermal contraction stress and ice formation, ensuring reliable operation. Similarly, in high speed and high frequency cycling applications, such as those associated with surge control on Subsea Pipelines, the quick response spring mechanism minimizes wear on the seats and disc, significantly enhancing the valve’s mean time between failure compared to designs with heavier moving parts. This robust performance under thermal and dynamic stress is a direct outcome of the axial design principle, providing a crucial margin of safety and efficiency in the most challenging operational contexts.

Lifetime Operational Cost and Maintenance Access

The fully inline and compact nature of the Axial Flow Check Valve also yields significant benefits in terms of lifetime operational expenditure and maintenance ease. While the valve is designed for a long service life, eventual inspection or part replacement is simplified by the valve's configuration. The streamlined body often permits access to the internal cage and spring assembly without needing to cut the valve from the line, particularly in smaller and medium sizes, thus significantly reducing downtime and labor costs. This reduced installation space and ease of in place servicing, especially in space constrained or difficult to access locations like Offshore Platforms, is a crucial economic advantage that complements the valve's high hydraulic performance, offering operators a lower total cost of ownership over the operational lifecycle of the pipeline or plant.

English

English русский

русский Français

Français 中文简体

中文简体 Português

Português Español

Español italiano

italiano عربى

عربى فارسی

فارسی

cryogenicvalves.jpg)

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province  +86-515-87398111

+86-515-87398111  office@trustvalve.com

office@trustvalve.com