Efficient Emptying for Silos, Tanks & Hoppers

"Complete Discharge. Zero Residue. Trust Valve—Bottom Outlets Perfected."

Efficient Emptying for Silos, Tanks & Hoppers

"Complete Discharge. Zero Residue. Trust Valve—Bottom Outlets Perfected."

Basic Types

|

|

|

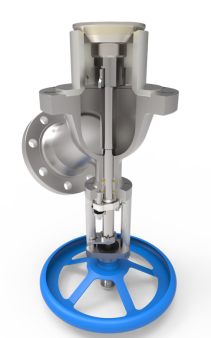

Rising Disc to Open |

Rising Disc to Close |

Basic Types

|

Features |

Benefits |

|

Disc Rise Mechanism |

Large, unobstructed opening for fast, complete emptying; minimizes residue in silos/tanks. |

|

Abrasion-Resistant Build |

Ductile iron, 316L stainless steel, or tungsten carbide-coated plungers withstand grit, grains, and chemicals. |

|

Tight Sealing |

PTFE/rubber seals prevent leakage when closed—critical for hazardous or valuable materials. |

|

Self-Cleaning Action |

Plunger movement dislodges stuck material, reducing clogs in sticky/granular service (cement, sugar). |

|

Easy Access |

Quick removal of plunger/seals for maintenance—cuts downtime in continuous discharge operations. |

Basic Types

Standard Bottom-Discharge Valves

Heavy-Duty Abrasive Service

Corrosion-Resistant Variants

Basic Types

Basic Types

How to Ensure Stable Sealing Performance of Disc Rise Plunger Valves for Bottom Discharging?

Understanding the Structural Features of Disc Rise Plunger Valves

Disc rise plunger valves are commonly used for bottom discharging in chemical, pharmaceutical, petrochemical, and high-purity material processing industries. Their structure relies on a plunger-driven disc that lifts vertically to allow medium discharge from the tank bottom. This vertical motion minimizes dead space and reduces the risk of residue accumulation inside the vessel. Jiangsu Tianyu Valve Manufacturing Co., Ltd., established in 1997 and specializing in the production of special material and special structure valves, develops plunger valves designed to operate under high temperature, high pressure, strong corrosion, ultra-low temperature, and ultra-high temperature conditions. The structural design of these valves—featuring a guided plunger movement, optimized sealing surfaces, and reinforced valve bodies—plays a crucial role in ensuring stable sealing performance, particularly when used in bottom discharging scenarios involving viscous, abrasive, or chemically aggressive media.

Selecting Suitable Materials for Sealing Stability

Material selection directly affects sealing stability, especially when the valve is exposed to harsh operating conditions. For corrosive media, stainless steels or alloy materials provide adequate resistance to chemical attack, preventing sealing surface deterioration. When the operating environment involves extreme temperatures, materials must maintain structural integrity and elasticity to withstand thermal cycling. Jiangsu Tianyu Valve Manufacturing Co., Ltd. offers plunger valves constructed from specialized alloys designed for hydrogenation, strong corrosion, and ultra-low temperature applications. These materials are chosen not only for durability but also for their ability to maintain stable sealing geometry during repeated opening and closing cycles. Combining suitable body materials with sealing elements such as metal-to-metal contact or reinforced soft seals contributes to a stable and reliable sealing interface.

| Working Condition | Material Requirement | Sealing Benefit |

| Strong Corrosion | Alloy steel / special stainless steel | Prevents corrosion wear on sealing surfaces |

| High Temperature | Heat-resistant alloys | Maintains sealing geometry under thermal stress |

| Ultra-Low Temperature | Cryogenic-grade stainless steel | Ensures sealing elasticity at low temperatures |

Optimizing Sealing Structure and Surface Finish

For disc rise plunger valves used in bottom discharging, sealing stability relies heavily on the precision of the sealing surface and the overall structure of the plunger-disc interface. A smooth and accurately machined sealing surface reduces leakage risks and minimizes wear during operation. Jiangsu Tianyu Valve Manufacturing Co., Ltd. applies controlled machining processes, fine grinding, and surface treatments to ensure uniform sealing contact. The plunger guiding mechanism is designed to retain alignment during movement, preventing tilting or uneven contact that could compromise sealing integrity. For applications involving solid particles or slurries, enhanced sealing surfaces reduce the risk of particle embedding, allowing the valve to maintain stable discharge performance even in demanding conditions.

Ensuring Proper Installation and Connection Methods

Installation factors significantly influence long-term sealing stability, especially for bottom discharging valves mounted directly beneath storage tanks or reactors. Misalignment between the valve and discharge outlet can create uneven sealing pressure, leading to leakage or accelerated wear. Jiangsu Tianyu Valve Manufacturing Co., Ltd. designs tank bottom valves and plunger valves with installation-friendly structures that maintain a smooth internal flow path, reducing turbulence and ensuring consistent sealing contact. Proper tightening torque, gasket selection, and flange compatibility must be carefully considered during installation to maintain uniform load distribution across the sealing surface. In high-pressure or high-temperature systems, secure connections help protect the valve body from vibration-induced displacement.

Managing Operating Conditions to Reduce Sealing Stress

Sealing performance can degrade if the valve is subjected to severe mechanical or thermal cycling without adequate control. Frequent switching under high pressure or rapidly changing temperatures may cause expansion, contraction, or mechanical impact that affects the sealing interface. Jiangsu Tianyu Valve Manufacturing Co., Ltd. designs valves with reinforced stems, durable sealing rings, and stable guiding structures to withstand repetitive operation. To maintain sealing stability, operators should avoid abrupt actuation motions and ensure that the medium flow does not cause excessive pressure spikes against the plunger or disc. Smooth operation, combined with controlled opening and closing speeds, helps extend sealing component lifespan and reduces the likelihood of micro-leakage over time.

| Operational Factor | Potential Result | Recommended Practice |

| Frequent high-pressure switching | Increased sealing wear | Use gradual actuation to reduce impact |

| Temperature fluctuations | Seal deformation | Implement controlled heating or cooling |

| Residue accumulation | Uneven sealing contact | Periodic flushing or cleaning |

Maintenance Strategies for Sustained Sealing Performance

Regular maintenance is essential for ensuring stable sealing performance over the valve’s service life. Periodic inspection of sealing surfaces, plunger alignment, and guiding structures helps identify early signs of wear or deformation. Jiangsu Tianyu Valve Manufacturing Co., Ltd. incorporates easy-maintenance features such as accessible sealing components and replaceable discs to support maintenance activities. For applications involving abrasive media or high-viscosity fluids, scheduled cleaning prevents residue from accumulating around the sealing interface. Lubrication of the plunger mechanism, where applicable, reduces friction and contributes to smoother actuation. A structured maintenance schedule increases sealing reliability and minimizes unexpected downtime.

Leveraging Customized Designs for Special Operating Requirements

In many industries, bottom discharging applications involve unique processing requirements that cannot be fully addressed by standard plunger valve designs. Jiangsu Tianyu Valve Manufacturing Co., Ltd. specializes in customizing valves using special materials, advanced sealing geometries, and engineered structures tailored to customer needs. For example, spray valves, multi way valves, and ultra-low temperature valves developed by the company demonstrate its capability to adapt valve structures to complex working conditions. Tailored bottom discharging plunger valves may incorporate reinforced sealing rings, modified disc shapes, or enhanced guiding mechanisms, allowing them to maintain sealing stability even in particularly challenging scenarios. Customized design plays a key role in maintaining sealing performance when operational conditions exceed conventional standards.

What Kind of Routine Maintenance Is Required for Disc Rise Plunger Valves for Bottom Discharging?

Understanding the Characteristics of Disc Rise Plunger Valves

Disc rise plunger valves used for bottom discharging are installed at the lowest point of tanks, reactors, or containers to ensure efficient medium discharge and reduce dead volume during processing. Their structural feature involves a vertically lifting plunger that raises the disc to open the flow path. This design provides stable flow control and smooth sealing contact, especially in applications handling viscous, corrosive, or high-purity fluids. Jiangsu Tianyu Valve Manufacturing Co., Ltd., established in 1997 and specializing in special material and special structure valves, manufactures plunger valves designed for high temperature, high pressure, strong corrosion, ultra-low temperature, and ultra-high temperature conditions. Understanding the characteristics of these valves helps define appropriate maintenance routines that ensure reliable long-term operation.

Inspecting Sealing Surfaces and Contact Interfaces

The sealing performance of disc rise plunger valves depends on the condition of the sealing surfaces between the disc and valve seat. Regular inspection is necessary to identify early wear, deformation, or residue buildup that may affect sealing stability. Jiangsu Tianyu Valve Manufacturing Co., Ltd. applies refined machining and surface treatment processes to improve sealing uniformity, but periodic checking is still essential under demanding operating environments. Operators should examine the disc contact area for scoring, corrosion traces, or embedded particles that could compromise sealing. In applications involving abrasive or high-viscosity media, more frequent inspection helps maintain consistent performance and reduces the risk of leakage during bottom discharging.

Cleaning Internal Flow Paths to Remove Residue

Because disc rise plunger valves are installed at the bottom of tanks, they are exposed to material residues, sediment, or crystallized particles that may accumulate over time. Routine cleaning preserves the smooth movement of the plunger and prevents obstruction of the flow channel. Jiangsu Tianyu Valve Manufacturing Co., Ltd. designs tank bottom valves and plunger valves with internal surfaces that minimize accumulation, but cleaning remains necessary for stable operation. Operators should flush the valve using compatible cleaning fluids or apply internal rinsing procedures to remove deposits before they harden. In systems handling corrosive or reactive chemicals, timely cleaning also prevents chemical attack on sealing surfaces.

| Residue Type | Potential Impact | Maintenance Action |

| Viscous medium | Movement resistance | Warm-water flushing or fluid rinsing |

| Crystallized deposits | Seal surface obstruction | Chemical cleaning or mechanical removal |

| Solid particles | Surface scratching | Filtering or pre-treatment of upstream fluid |

Checking Plunger Alignment and Guiding Components

The vertical movement of the plunger must remain accurately aligned to ensure uniform sealing contact. Misalignment can cause tilted disc movement, uneven wear, or leakage. Jiangsu Tianyu Valve Manufacturing Co., Ltd. enhances plunger guiding structures to maintain stability under challenging conditions, including high temperature and strong corrosion environments. Routine maintenance involves verifying that the guiding sleeve, plunger stem, and lifting mechanism remain in proper condition without excessive clearance or deformation. Operators should ensure that the plunger moves smoothly throughout its stroke without friction points. When deposits accumulate around guiding components, cleaning and lubrication help restore smooth mechanical operation.

Monitoring Actuation Mechanism and Drive Components

Actuation mechanisms such as manual gear, pneumatic actuators, or electric actuators must operate consistently to maintain stable valve performance. Regular monitoring ensures that the drive components do not suffer from wear, insufficient lubrication, or improper torque. Jiangsu Tianyu Valve Manufacturing Co., Ltd. equips plunger valves with actuator-compatible designs to support automated operation in complex process environments. Routine maintenance includes checking actuator mounting alignment, testing response speed, and ensuring that limit switches or control signals function properly. Lubrication of moving parts within the actuator assembly helps preserve mechanical efficiency.

Evaluating Material Integrity Under Special Working Conditions

Disc rise plunger valves used in high temperature, high pressure, strong corrosion, or ultra-low temperature applications require special material designs. Jiangsu Tianyu Valve Manufacturing Co., Ltd. manufactures valves using alloys, cryogenic-grade materials, and corrosion-resistant steels to meet demanding conditions. Routine maintenance should include checking for surface discoloration, stress marks, or minor deformation that may indicate material fatigue. In hydrogenation or corrosive environments, operators should inspect internal surfaces for pitting or erosion. In ultra-low temperature applications, seals and elastomers must retain elasticity, making regular inspection critical to maintaining discharge performance and avoiding unexpected sealing failures.

| Operating Condition | Potential Material Issue | Maintenance Recommendation |

| High Temperature | Thermal stress | Check body thinning and structural deformation |

| Strong Corrosion | Pitting or erosion | Inspect corrosion-prone surfaces frequently |

| Cryogenic Conditions | Seal hardening | Replace seals showing reduced elasticity |

Maintaining Sealing Components and Replaceable Parts

Routine maintenance should also involve evaluating the condition of replaceable sealing components such as O-rings, sealing rings, and metal-seal interfaces. Even with robust designs, these components experience gradual wear during repeated operation. Jiangsu Tianyu Valve Manufacturing Co., Ltd. designs plunger valves with accessible sealing assemblies to simplify replacement work. Operators should follow scheduled replacement intervals based on operating frequency and process conditions. For valves in continuous operation or exposed to abrasive media, sealing components may require more frequent replacement to maintain discharge reliability.

Maintaining Environmental and Installation Stability

The external installation environment can also affect the performance of disc rise plunger valves. Vibrations, temperature fluctuations, or improper pipeline support may lead to misalignment or sealing stress. Jiangsu Tianyu Valve Manufacturing Co., Ltd. provides installation-friendly valve structures that support stable mounting under tank bottoms and reactors. Routine inspection should verify that flanges are securely tightened, support structures remain stable, and surrounding pipelines do not exert undue mechanical force on the valve. Ensuring stable installation conditions helps maintain proper sealing pressure and consistent actuation performance.