-

Rising Stem Mechanism for Axial Flexibility and Visual Positioning:

The hallmark feature of Rising Stem Ball Valves is the axially movable stem, which rises when the valve is opened and lowers when closed. This movement not only provides a clear visual indication of valve status but also introduces a degree of mechanical flexibility into the valve assembly. The axial freedom of the stem allows the internal components to adjust to minor shifts in the pipeline or thermal expansion without transmitting excessive stress to the ball, seats, or body. As a result, even under fluctuating temperature conditions or slight misalignment of piping, the valve maintains reliable operation and tight shutoff, while the visual open/closed indicator ensures operators can monitor position at a glance. -

Floating or Trunnion-Mounted Ball Design for Stress Compensation:

Rising Stem Ball Valves utilize either floating or trunnion-mounted ball designs to accommodate thermal and mechanical stresses. In floating ball valves, the ball is held in place by the seats but is allowed slight lateral movement along the flow axis. This movement enables the seats to absorb forces from thermal expansion or misaligned piping, maintaining a tight seal. In trunnion-mounted ball valves, the ball is supported at the top and bottom by trunnion bearings, which take on mechanical loads from pressure, vibration, or expansion. Both configurations reduce the stress transmitted to the sealing surfaces, thereby preserving valve integrity and minimizing wear during long-term operation. -

Resilient Seat Materials and Self-Adjusting Seal Mechanisms:

Rising Stem Ball Valves employ seats made of resilient, elastomeric, or composite materials such as PTFE, RPTFE, or reinforced polymers. These materials allow controlled deformation under pressure, enabling the valve to maintain a tight seal even as the ball or body shifts slightly due to thermal expansion or vibration. Many designs include spring-loaded or self-adjusting seat mechanisms, which automatically compensate for minor axial or lateral movement of the ball, ensuring consistent sealing performance across a wide range of operating conditions. This design also accommodates thermal cycling, which can otherwise create gaps between rigid components. -

Stress-Relieved Body and Bonnet Construction:

The valve body, bonnet, and flanges are engineered to allow minor flexing or thermal movement without transmitting excessive forces to the internal components. Features such as stress-relief grooves, precisely machined flanged connections, and slightly flexible bolted joints enable the valve to absorb pipeline expansion and contraction. This ensures that thermal growth of the piping or the valve itself does not compromise sealing surfaces, mechanical alignment, or structural integrity. The robust body design also supports vibration resistance, minimizing the risk of fatigue or deformation during high-pressure operations. -

Flexible Stem Packing and Leak Prevention:

The Rising Stem Ball Valve uses adjustable gland packing or flexible sealing materials around the stem, which maintain a leak-tight seal while allowing the stem to move axially. This design is critical for accommodating vibration, pipeline shifting, or thermal growth, as the stem can expand or contract without breaking the seal. The packing can often be tightened or serviced without removing the valve from the pipeline, ensuring continued leak prevention under varying operational conditions. -

Vibration Dampening and Mechanical Isolation Features:

High-quality Rising Stem Ball Valves incorporate internal bushings, bearings, or vibration-absorbing inserts to reduce the impact of mechanical shock, vibration, or pulsation from the pipeline. These features prevent the transfer of vibrational forces to the seats and stem, reducing wear and extending service life. By isolating sensitive components from pipeline vibration, the valve maintains tight shutoff and operational reliability even in challenging industrial environments such as chemical plants, refineries, or water treatment facilities.

- Home

- Products

- Specialty Valves

- Cryogenic Valves

- Ultra High Pressure Angle Type Valves

- Disc Rise Plunger Valves for Bottom Discharging

- Inclined-Stem Tank Bottom Ball Valves

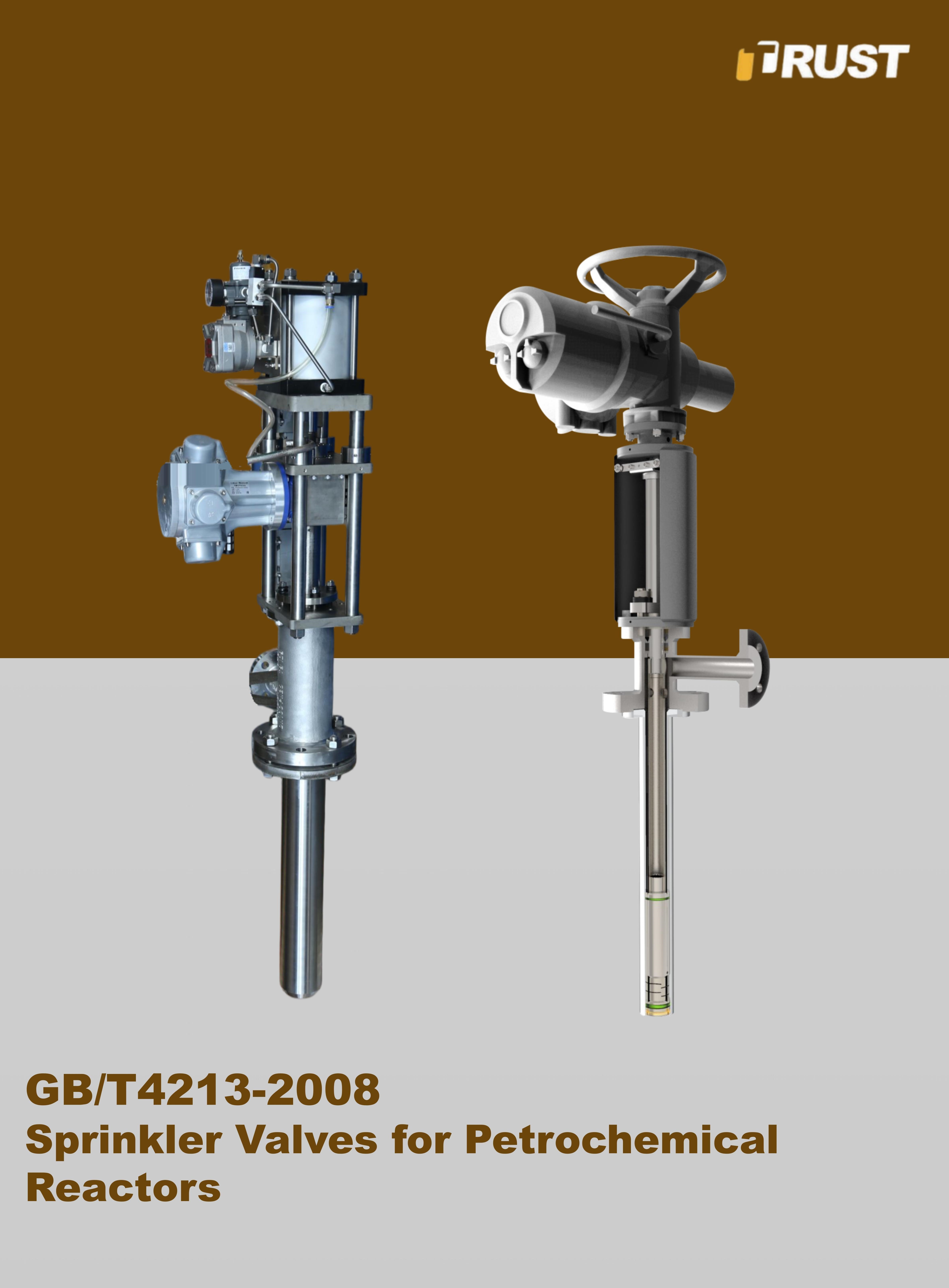

- Sprinkler Valves for Petrochemical Reactors

- Double Block and Bleed (DBB) Valves

- Pig Valves for Oil & Gas Pipelines

- LNG Loading Arm Emergency Release Coupling (ERC) Valves

- Multi-Port Selector Valves

- Axial Flow Shutoff & Control Valve

- Rising Stem Ball Valves

- Quarter Turn Valves

- Gate/Globe/Check Valves

- Specialty Valves

- Industries

- Engineering

- Quality

- News

- Resources

- Contact

English

English русский

русский Français

Français 中文简体

中文简体 Português

Português Español

Español italiano

italiano عربى

عربى فارسی

فارسی

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province  +86-515-87398111

+86-515-87398111  office@trustvalve.com

office@trustvalve.com