-

Pipeline Compatibility and Dimensional Requirements of the Plunger valve: The successful integration of the Plunger valve into existing pipeline or fluid control systems requires careful verification of dimensional compatibility, including pipe diameter, flange standards, connection types, and pressure ratings. The valve must match the nominal pipe size (NPS) or diameter specifications of the system to ensure proper flow characteristics and avoid restrictions or turbulence that could affect operational efficiency. Connection configurations such as flanged, threaded, or welded joints must comply with industry standards (e.g., ANSI, DIN, or ISO) used within the existing infrastructure. Sufficient installation space must be provided to accommodate the valve body, actuator components, and maintenance access requirements. Proper alignment between the Plunger valve and pipeline is critical to prevent mechanical stress, leakage, or premature wear. Ensuring dimensional accuracy and mechanical compatibility supports reliable performance, stable flow control, and long-term structural integrity of the entire fluid handling system.

-

Pressure Rating and Flow Capacity Matching of the Plunger valve: When installing the Plunger valve, it is essential to verify that its pressure class, flow coefficient, and operational range are compatible with the system’s design parameters. The valve must be capable of handling the maximum operating pressure, pressure fluctuations, and potential surge conditions present within the pipeline. Selecting a Plunger valve with appropriate flow capacity ensures efficient fluid regulation without excessive pressure drop or flow restriction. Engineers must also evaluate the system’s flow characteristics, including velocity, turbulence levels, and expected load variations, to ensure optimal valve performance. Incorrect sizing or mismatched pressure ratings can result in unstable operation, reduced control accuracy, or potential safety risks. Proper pressure and capacity matching allows the Plunger valve to operate within its designed performance range, ensuring accurate flow control, energy efficiency, and system reliability.

-

Fluid Compatibility and Material Selection Considerations for the Plunger valve: The materials used in the construction of the Plunger valve must be compatible with the fluid medium handled by the system to prevent corrosion, chemical degradation, or contamination. Factors such as fluid composition, temperature, viscosity, and potential presence of abrasive particles must be evaluated when selecting appropriate valve body materials, sealing elements, and internal components. For example, corrosive chemicals may require stainless steel or specialized alloy construction, while high-temperature fluids may demand heat-resistant sealing materials. Incompatible materials can lead to premature failure, leakage, or compromised flow control performance. Proper material compatibility ensures long-term durability, maintains sealing integrity, and prevents adverse chemical reactions that could affect system safety or operational stability.

-

Installation Orientation and Flow Direction Requirements of the Plunger valve: The Plunger valve must be installed according to specified orientation and flow direction guidelines to achieve optimal performance and prevent operational issues. Many plunger valves are designed for specific flow directions to ensure proper sealing, pressure balancing, and flow regulation characteristics. Incorrect installation may result in increased wear, reduced control precision, or compromised shut-off performance. The installation orientation—whether horizontal or vertical—must be evaluated based on manufacturer recommendations and system design constraints. Adequate support structures and mounting arrangements should be provided to prevent mechanical strain caused by pipeline weight or vibration. Correct installation positioning enhances flow stability, improves operational efficiency, and extends the service life of the valve.

-

Actuation System Integration and Control Interface Compatibility of the Plunger valve: Integrating the Plunger valve into an existing system requires compatibility between the valve’s actuation mechanism and the facility’s control infrastructure. Whether the valve is manually operated or equipped with pneumatic, hydraulic, or electric actuators, the actuation system must align with available power sources, control signals, and automation protocols. Proper integration with control systems such as SCADA or distributed control systems ensures precise valve positioning, real-time monitoring, and responsive flow regulation. The installation process should also consider feedback sensors, position indicators, and safety interlocks to maintain reliable operation. Ensuring control interface compatibility enhances process automation, operational efficiency, and system responsiveness under varying operating conditions.

-

Pipeline Stress Management and Vibration Control for the Plunger valve: Proper installation of the Plunger valve requires careful management of mechanical stress and vibration within the pipeline system. The valve should not be subjected to excessive external loads from misaligned pipes, thermal expansion, or unsupported pipeline sections, as these factors can affect sealing performance and structural integrity. Installation may require the use of flexible connectors, expansion joints, or vibration dampening supports to reduce mechanical stress transmission. The system should be evaluated for potential flow-induced vibration, which could impact valve stability and long-term performance. Effective stress and vibration control measures ensure consistent operation, reduce maintenance requirements, and protect both the valve and surrounding pipeline infrastructure.

- Home

- Products

- Specialty Valves

- Cryogenic Valves

- Ultra High Pressure Angle Type Valves

- Disc Rise Plunger Valves for Bottom Discharging

- Inclined-Stem Tank Bottom Ball Valves

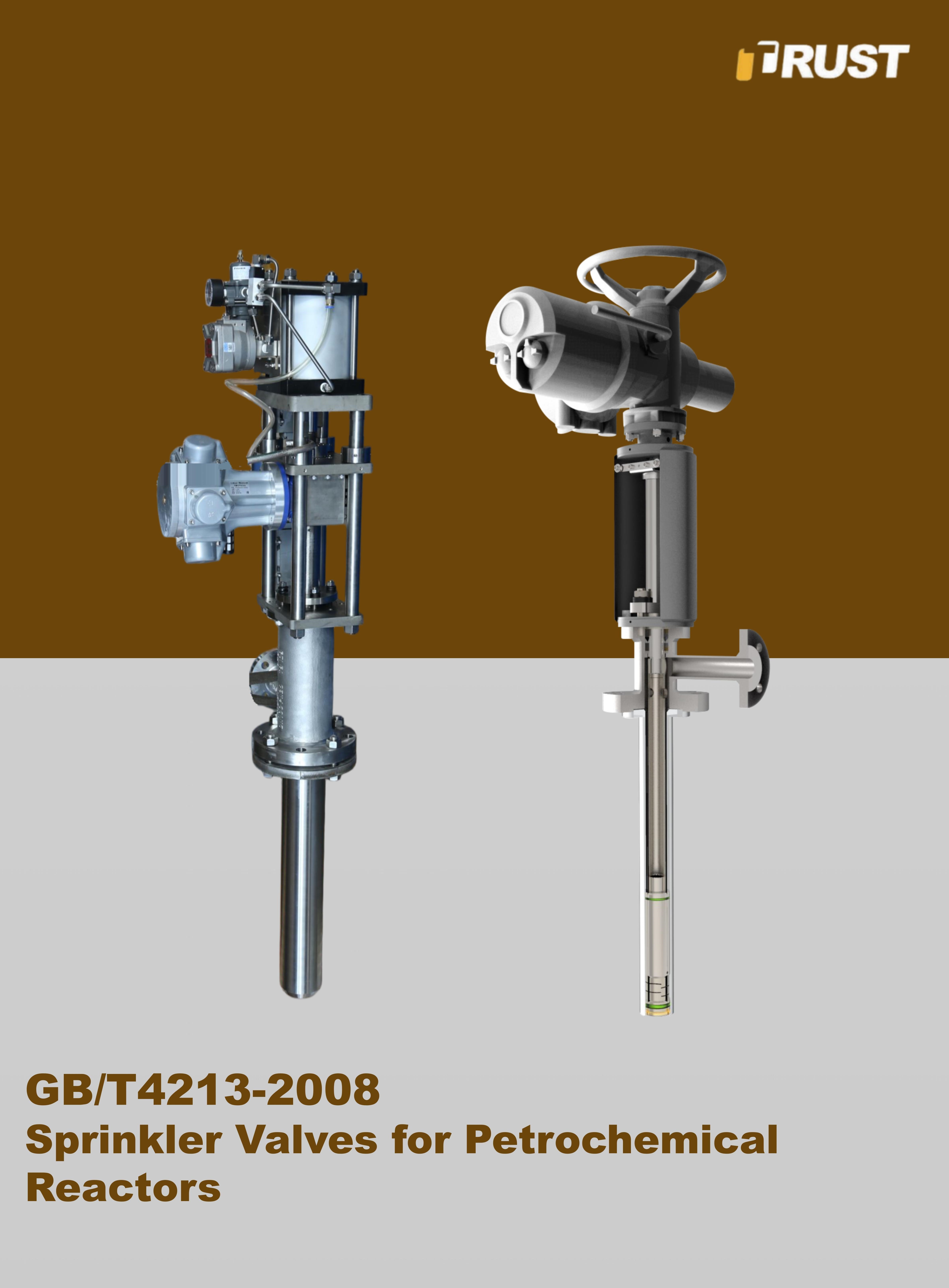

- Sprinkler Valves for Petrochemical Reactors

- Double Block and Bleed (DBB) Valves

- Pig Valves for Oil & Gas Pipelines

- LNG Loading Arm Emergency Release Coupling (ERC) Valves

- Multi-Port Selector Valves

- Axial Flow Shutoff & Control Valve

- Rising Stem Ball Valves

- Quarter Turn Valves

- Gate/Globe/Check Valves

- Specialty Valves

- Industries

- Engineering

- Quality

- News

- Resources

- Contact

English

English русский

русский Français

Français 中文简体

中文简体 Português

Português Español

Español italiano

italiano عربى

عربى فارسی

فارسی

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province  +86-515-87398111

+86-515-87398111  office@trustvalve.com

office@trustvalve.com