Valves are essential components in fluid control systems across a wide range of industries, from manufacturing to energy production. Each type of valve offers distinct advantages depending on the application, pressure requirements, and operational conditions. Among the most commonly used valve types are ball valves, piston valves, and plunger valves. Trust Valve (Jiangsu) Co., Ltd., a leading manufacturer of high-quality valves, offers these and other valve solutions to industries worldwide.

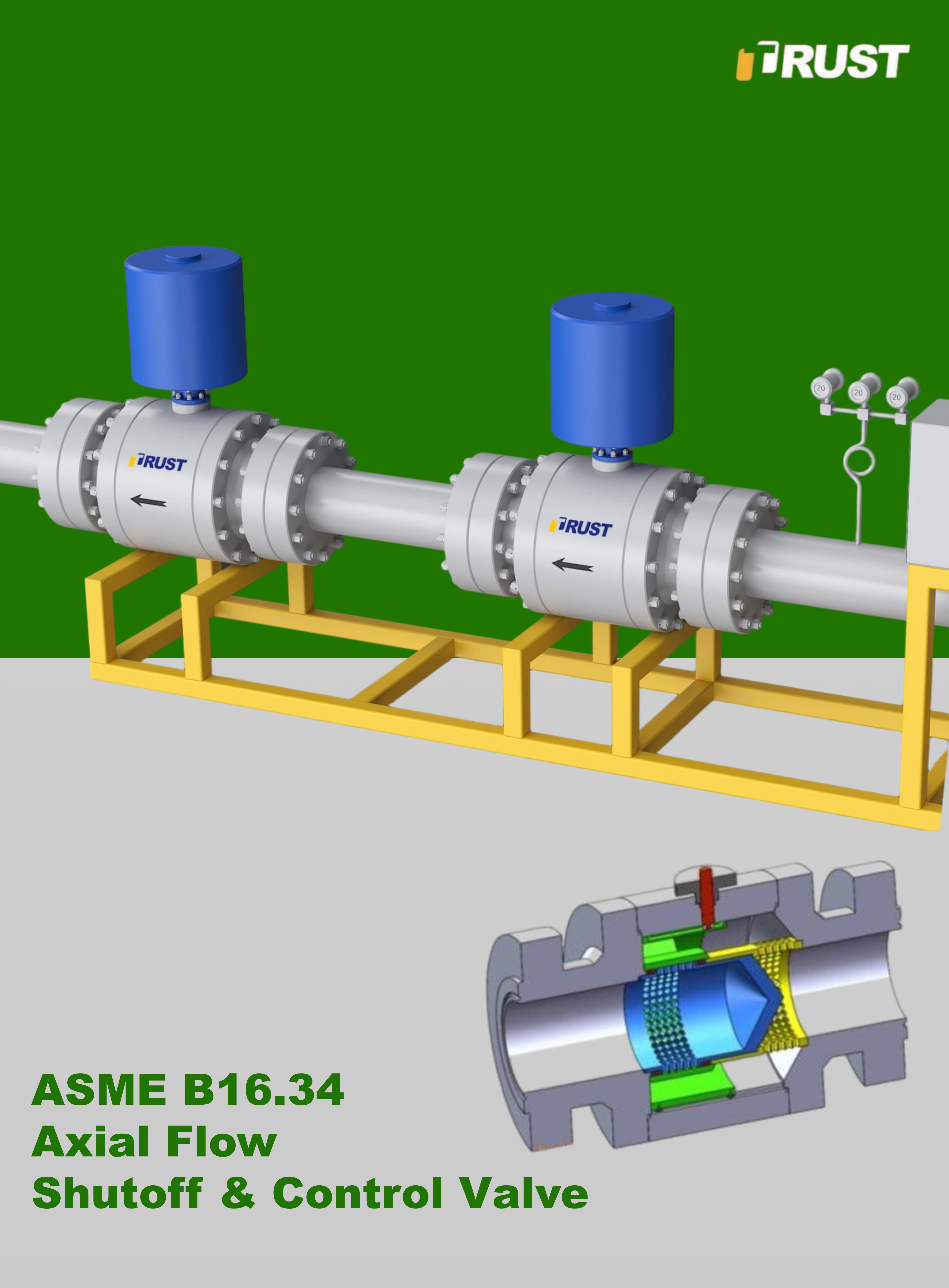

1. Ball Valves: Precision and Reliability in Fluid Control

Ball valves are among the most popular valve types, known for their simplicity, reliability, and high performance. At Trust Valve (Jiangsu) Co., Ltd., we specialize in designing and producing a wide range of ball valves tailored to meet the demands of various industries, including petrochemical, water treatment, and HVAC systems.

Design and Functionality:

A ball valve consists of a spherical ball with a hole through its center (the bore). When the valve is open, the bore is aligned with the flow path, allowing fluid to pass through. When the valve is closed, the ball rotates 90 degrees, and the bore is positioned perpendicular to the flow path, effectively blocking the fluid. The mechanism is straightforward, but highly effective in regulating flow.

Ball valves are typically operated by either manual actuators or automated electric or pneumatic actuators. The design of the valve ensures that it can be operated quickly and efficiently, providing a reliable seal to prevent leakage when closed.

Key Features:

- Quick and Easy Operation: Ball valves are ideal for on/off control because they provide a rapid shutoff, which makes them suitable for applications where rapid isolation of fluid flow is essential.

- Excellent Sealing Performance: Due to their robust construction and tight sealing mechanisms, ball valves are perfect for applications where leakage control is critical. Their ability to shut off flow completely and quickly makes them particularly useful in systems requiring secure shutoff.

- Long Service Life: With fewer moving parts, ball valves require less maintenance and offer exceptional durability. The smooth internal surface of the valve helps to reduce wear and tear, contributing to longer service intervals.

- Wide Range of Sizes and Materials: Ball valves come in various sizes and materials to accommodate different fluid types, pressures, and temperatures. At Trust Valve (Jiangsu) Co., Ltd., we provide ball valves made from materials such as stainless steel, carbon steel, and brass to ensure compatibility with a wide range of industries.

Applications:

Ball valves are used across many industries, including:

- Water and wastewater treatment: Ball valves are frequently employed in water distribution and treatment plants for their efficiency in controlling water flow.

- Oil and gas: These valves are crucial in the oil and gas industry for the control of high-pressure fluids and gases.

- Chemical processing: Due to their strong sealing properties, ball valves are ideal for controlling corrosive chemicals and preventing leaks.

Ball valves from Trust Valve (Jiangsu) Co., Ltd. are designed to meet the high standards required by industries such as oil & gas, power generation, and water treatment, providing secure and efficient flow control.

2. Piston Valves: High-Pressure Solutions for Fluid Control

Piston valves are essential in applications requiring precise control and high-pressure handling. These valves use a piston or similar component to regulate fluid flow, making them suitable for industries where high-pressure systems need precise flow regulation and control. Trust Valve (Jiangsu) Co., Ltd. provides piston valves that are engineered to perform reliably under demanding conditions, ensuring safety and efficiency.

Design and Functionality:

A piston valve consists of a cylindrical piston that moves within a chamber to open or close the fluid passage. The piston is often sealed with O-rings or other sealing mechanisms to prevent leakage. By moving the piston, the valve either blocks the flow completely or adjusts the flow rate by positioning the piston to allow a certain amount of fluid to pass through. This design makes piston valves ideal for applications requiring precise control over flow rates, particularly in systems under high pressure.

The piston is typically actuated by pneumatic, hydraulic, or electric actuators, depending on the application and the required control level. The motion of the piston can either be linear or rotary, depending on the design.

Key Features:

- High-Pressure Performance: Piston valves are designed to withstand high pressures and extreme temperature variations, making them ideal for use in industries like power generation, hydraulic systems, and high-pressure steam systems.

- Precise Flow Control: These valves offer fine-tuned flow regulation, which is particularly important in applications like chemical dosing, steam systems, and hydraulic circuits.

- Durable Construction: Piston valves are built for heavy-duty use and are typically made from materials that resist corrosion, wear, and erosion, such as stainless steel or carbon steel.

Applications:

Piston valves are particularly beneficial in high-pressure fluid systems. Some common applications include:

- Hydraulic systems: Piston valves are commonly used in hydraulic systems where high pressure and precision control are required.

- Power plants: Piston valves control steam flow in power plants, helping to regulate the pressure and temperature within boilers and turbines.

- Aerospace and automotive: These valves play a role in controlling fluids in both aerospace and automotive systems, such as in fuel management and braking systems.

At Trust Valve (Jiangsu) Co., Ltd., we specialize in manufacturing piston valves that meet the highest standards of quality and performance. Our piston valves are built to endure harsh environments and provide reliable operation, ensuring the safe and efficient operation of critical systems.

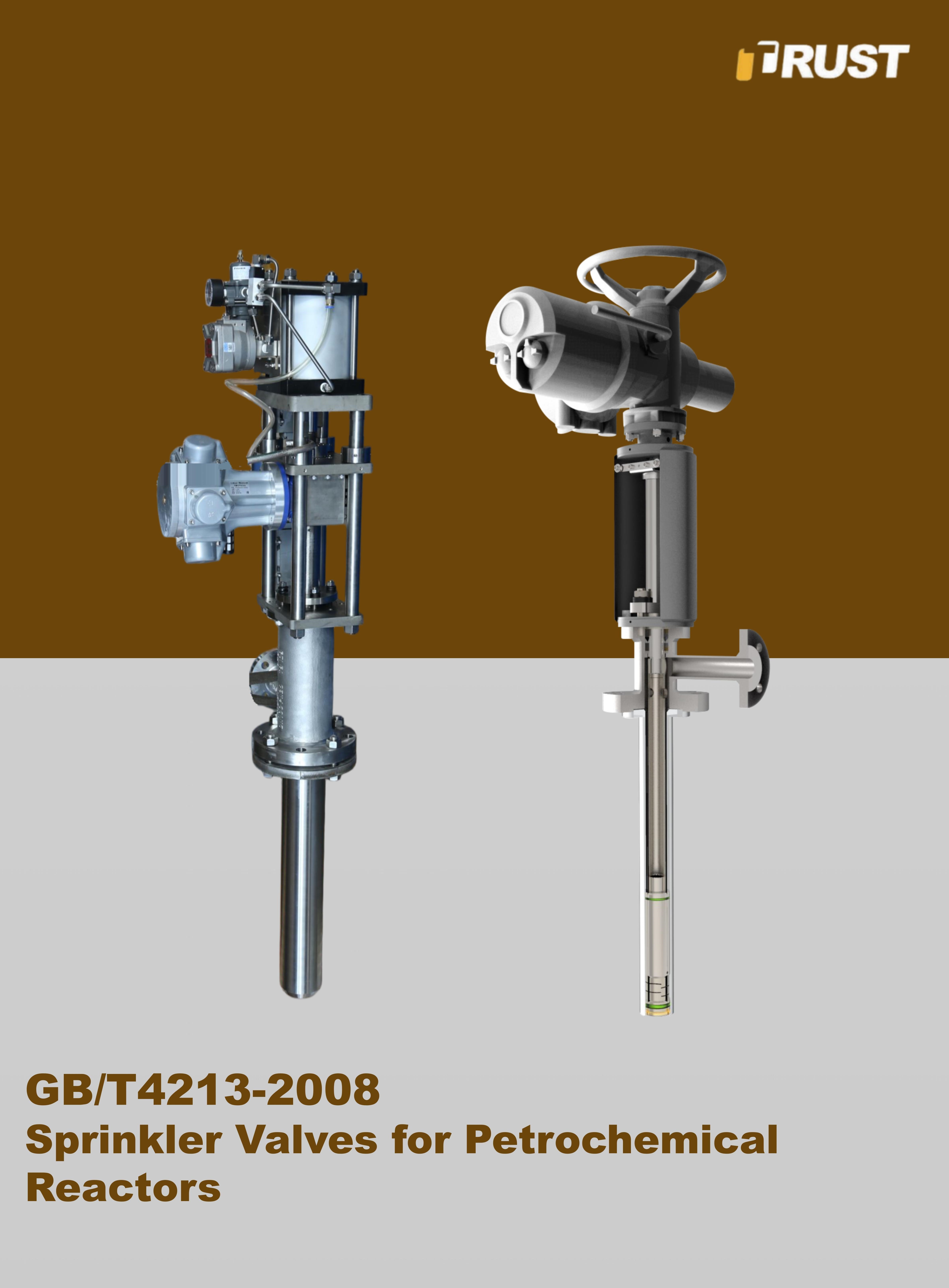

3. Plunger Valves: Robust Control in High-Flow Applications

Plunger valves are ideal for managing large volumes of fluid in systems that require reliable, durable control. These valves use a plunger, which moves up and down inside a cylinder to regulate fluid flow. The plunger either blocks or permits the flow of fluids based on its position, providing an effective means of controlling flow in large-scale applications. Trust Valve (Jiangsu) Co., Ltd. produces high-quality plunger valves designed to meet the rigorous demands of industries like water treatment, mining, and chemical processing.

Design and Functionality:

In a plunger valve, a cylindrical plunger moves within a valve body to either open or close the flow passage. The plunger may be actuated manually or through an automated system, and it is designed to create a tight seal when closed, ensuring no fluid escapes. The ability of the plunger to handle large volumes of fluid with minimal pressure drop makes this valve type ideal for high-flow applications.

Key Features:

- High Flow Capacity: Plunger valves are designed to handle large volumes of fluid, making them ideal for applications that involve significant fluid movement, such as in irrigation systems or slurry transportation.

- Heavy-Duty Construction: These valves are built with robust materials that can handle abrasive or corrosive fluids. This makes them suitable for industries where harsh materials or chemicals are present, such as in mining or wastewater treatment.

- Flexible Actuation: Plunger valves can be actuated manually, pneumatically, or electrically, depending on the application requirements. This versatility makes them adaptable to a variety of industrial settings.

Applications:

Plunger valves are used in various applications that require reliable control of large volumes of fluid:

- Water treatment: These valves are commonly used in water treatment plants for the regulation of large volumes of water.

- Slurry handling: Plunger valves are frequently used in industries that handle slurries or viscous fluids, such as in mining or cement manufacturing.

- Irrigation: In agricultural systems, plunger valves control the flow of water in irrigation channels and pipelines.

Trust Valve (Jiangsu) Co., Ltd. manufactures plunger valves that are designed to offer high performance in demanding industrial applications. Our plunger valves ensure reliable operation and help optimize fluid control in large-scale systems.

English

English русский

русский Français

Français 中文简体

中文简体 Português

Português Español

Español italiano

italiano عربى

عربى فارسی

فارسی

cryogenicvalves.jpg)

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province  +86-515-87398111

+86-515-87398111  office@trustvalve.com

office@trustvalve.com