Why Choose Special Alloy Valves? What Are Their Unique Advantages?

In modern industry, valves are essential components for controlling the flow of fluids and gases. They are widely used in fields such as oil and gas, chemical engineering, power generation, and marine applications. However, many industrial environments are filled with extreme conditions, such as high temperatures, high pressures, strong corrosion, and cryogenic temperatures. Traditional valves often fail to meet the long-term performance demands in such environments. Choosing special alloy valves is crucial for ensuring equipment safety and operational reliability.

The reason why special alloy valves perform excellently in extreme conditions lies in the materials they are made from. These valves are constructed using alloys that contain elements such as nickel, titanium, chromium, and molybdenum, which provide exceptional resistance to corrosion, high temperature, and oxidation. Compared to conventional valves, special alloy valves can withstand higher temperatures and pressures, while also enduring long-term operation in corrosive environments such as acids, alkalis, and saltwater. This makes them ideal for use in industries such as petrochemical, nuclear energy, offshore oil and gas platforms, and natural gas pipelines.

Trust Valve (Jiangsu) Co., Ltd. is one of China’s leading manufacturers of special alloy valves. Since our establishment in 1997, we have dedicated ourselves to providing high-quality, high-performance valves designed for a variety of harsh environments. Whether dealing with high temperature, high pressure, strong corrosion, or low temperature conditions, our special alloy valves ensure safe and reliable operation of your systems.

Our valves not only offer exceptional durability but also significantly reduce maintenance and replacement costs, lowering downtime and extending operational efficiency. By choosing our meticulously designed and manufactured special alloy valves, you can ensure the long-term stability of your systems and improve productivity.

Why Can Special Alloy Valves Meet the Most Stringent Industrial Demands?

Special alloy valves are capable of handling extreme working conditions due to the innovation in both their materials and structural design. Unlike conventional carbon steel or stainless steel valves, special alloy valves are made from materials that are specifically engineered to resist high temperatures, corrosion, and oxidation. These alloys are treated to withstand environments of ultra-high temperatures, cryogenic conditions, and aggressive chemicals without compromising performance.

For example, alloys such as nickel-based alloys, titanium alloys, and chromium alloys maintain their strength and toughness even at extremely high temperatures, which can exceed 1000°C. This ensures that these valves do not suffer from deformation or failure under high temperature conditions, as is often the case with standard valves.

Special alloy valves offer exceptional corrosion resistance. In industries like petrochemical, marine, and oil and gas, valves are frequently exposed to corrosive media such as strong acids, alkalis, and saltwater. Special alloy valves can resist such aggressive chemicals, significantly extending the service life of the valves and reducing the need for frequent replacements.

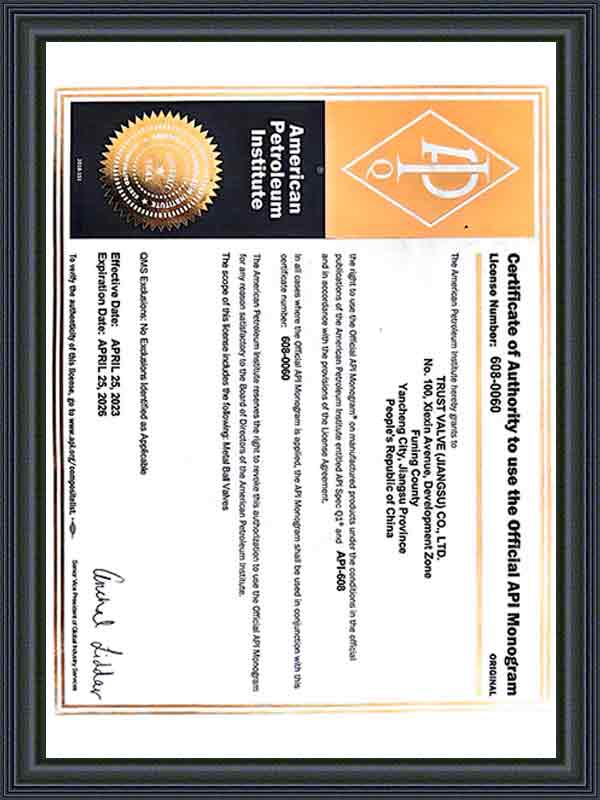

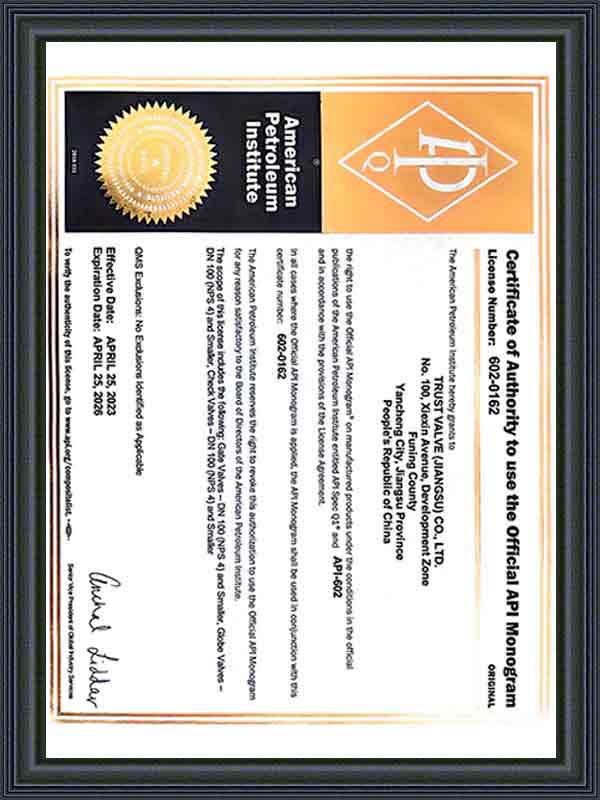

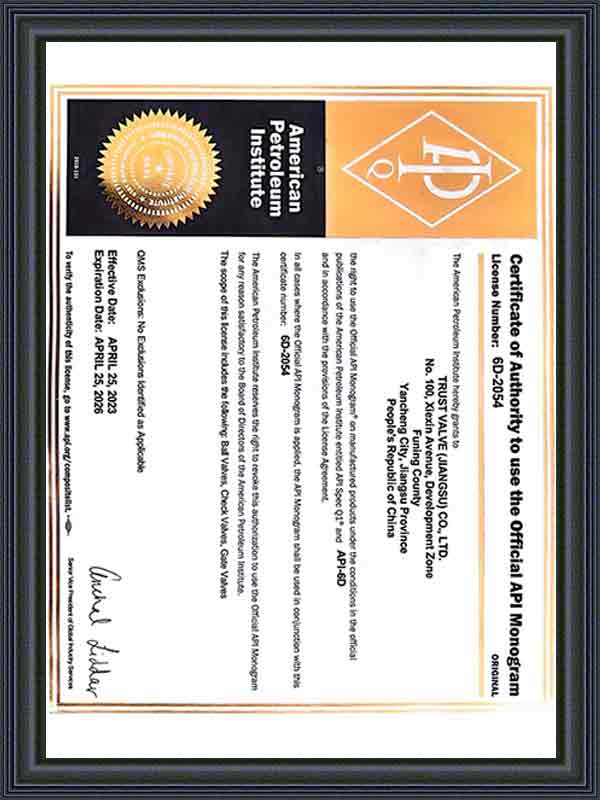

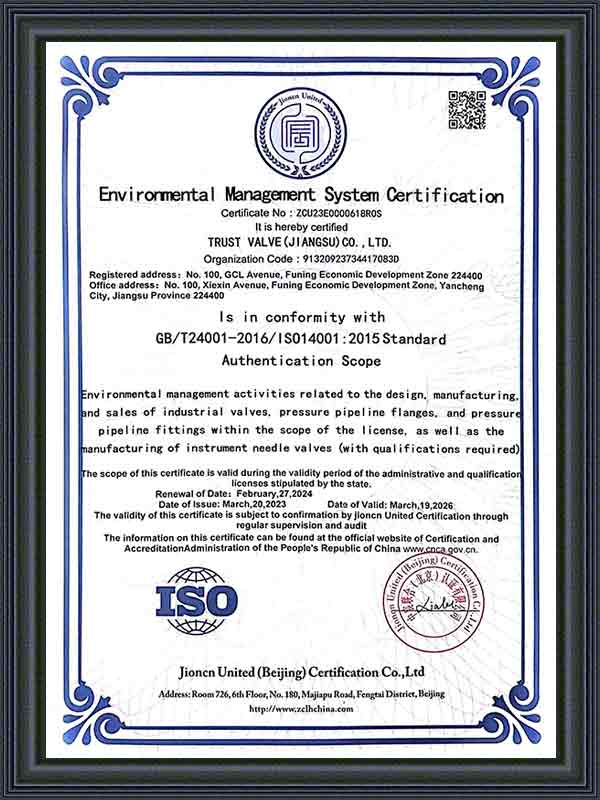

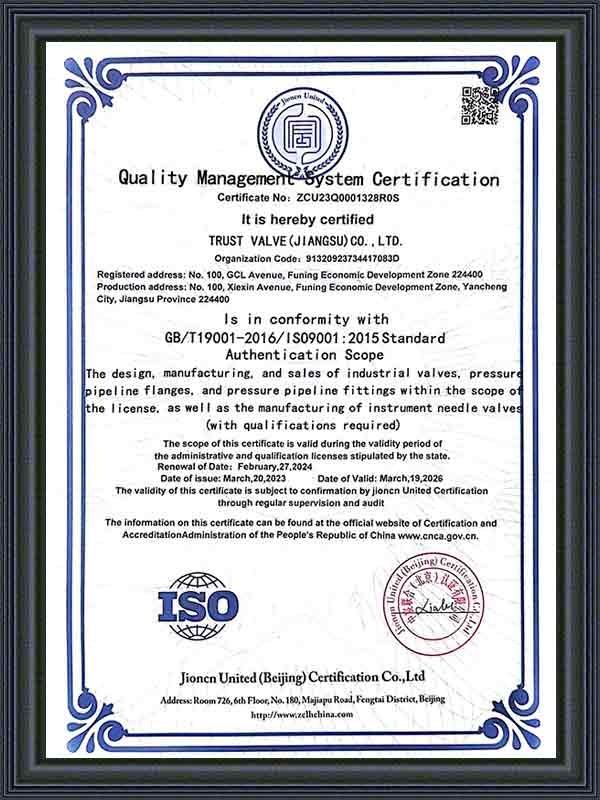

At Trust Valve (Jiangsu) Co., Ltd., we leverage advanced manufacturing technology and years of industry experience to provide valves that are specifically designed to meet the demands of extreme operating conditions. Our products not only comply with the ISO9001 quality management system certification but also meet various international standards, including API607 fireproof, SIL safety ratings, CE certification, and more, ensuring stable performance in even the most challenging environments.

To ensure the high performance of our special alloy valves, we are equipped with over 100 sets of specialized lathes and CNC machining centers, with an annual production capacity of approximately 25,000 sets. Our company is capable of providing customized solutions for high temperature, high pressure, and corrosive applications. Whether your needs require valves for extreme heat, pressure, or corrosion, we can provide the ideal product.

Why Are Our Special Alloy Valves the Best Choice for You?

As a leading valve manufacturer in China, Trust Valve (Jiangsu) Co., Ltd. has been committed to technological innovation and quality control since our founding. With years of industry experience, we provide our domestic and international customers with high-quality special alloy valves. Our company holds ISO9001 quality management certification, HSE Environmental Health & Safety Management System certification, and several international certifications, ensuring the high quality and performance of every valve we produce.

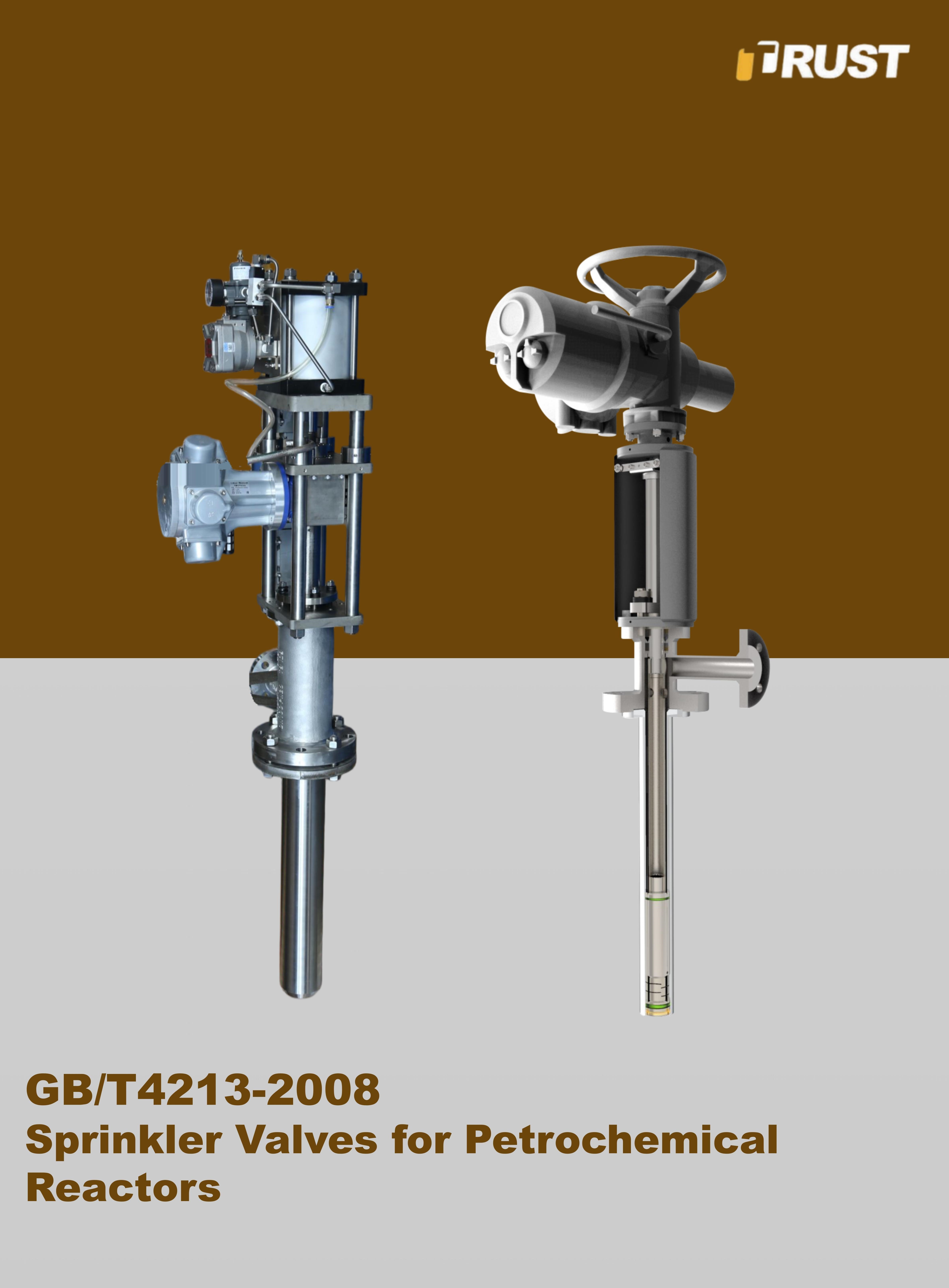

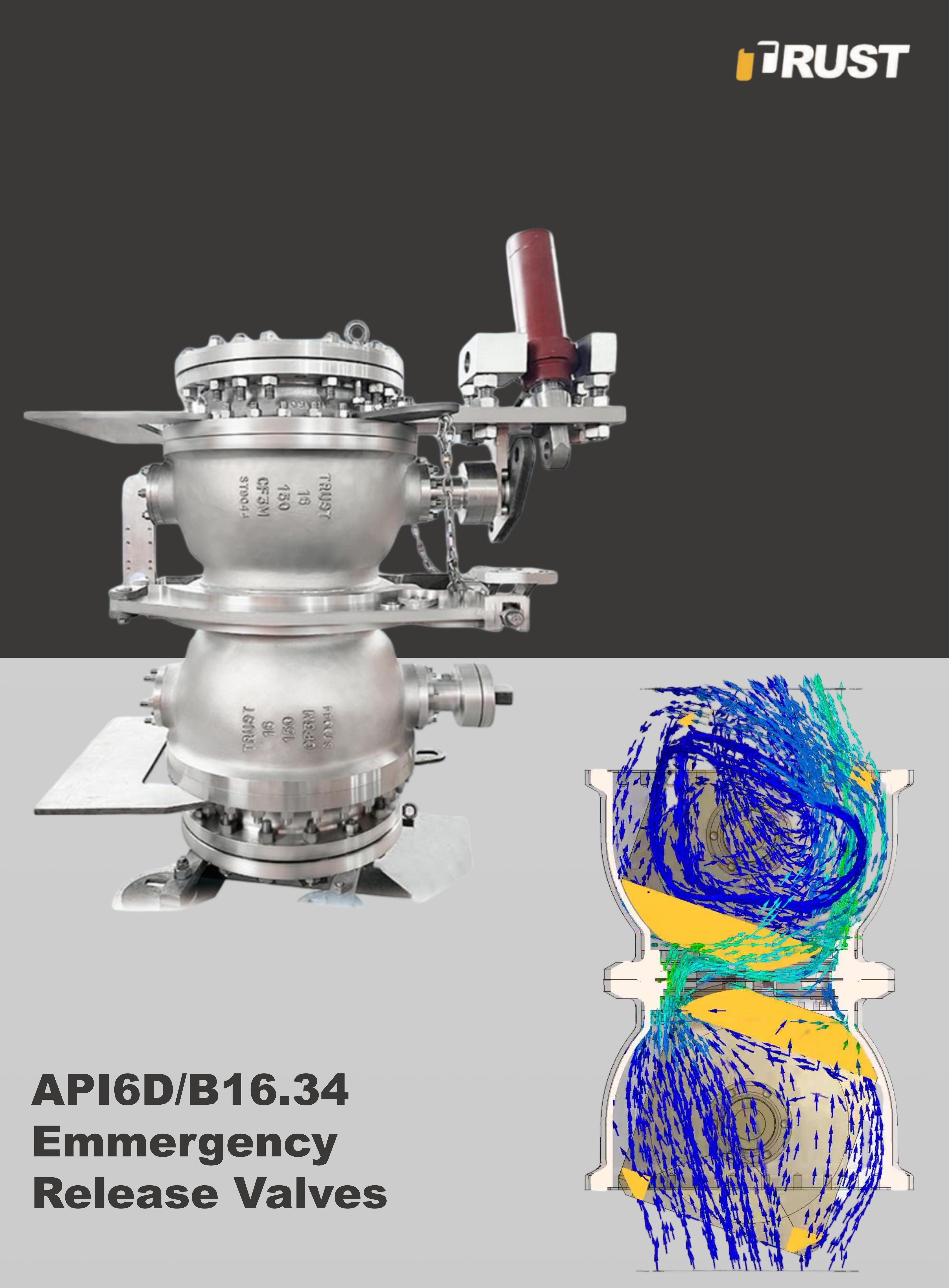

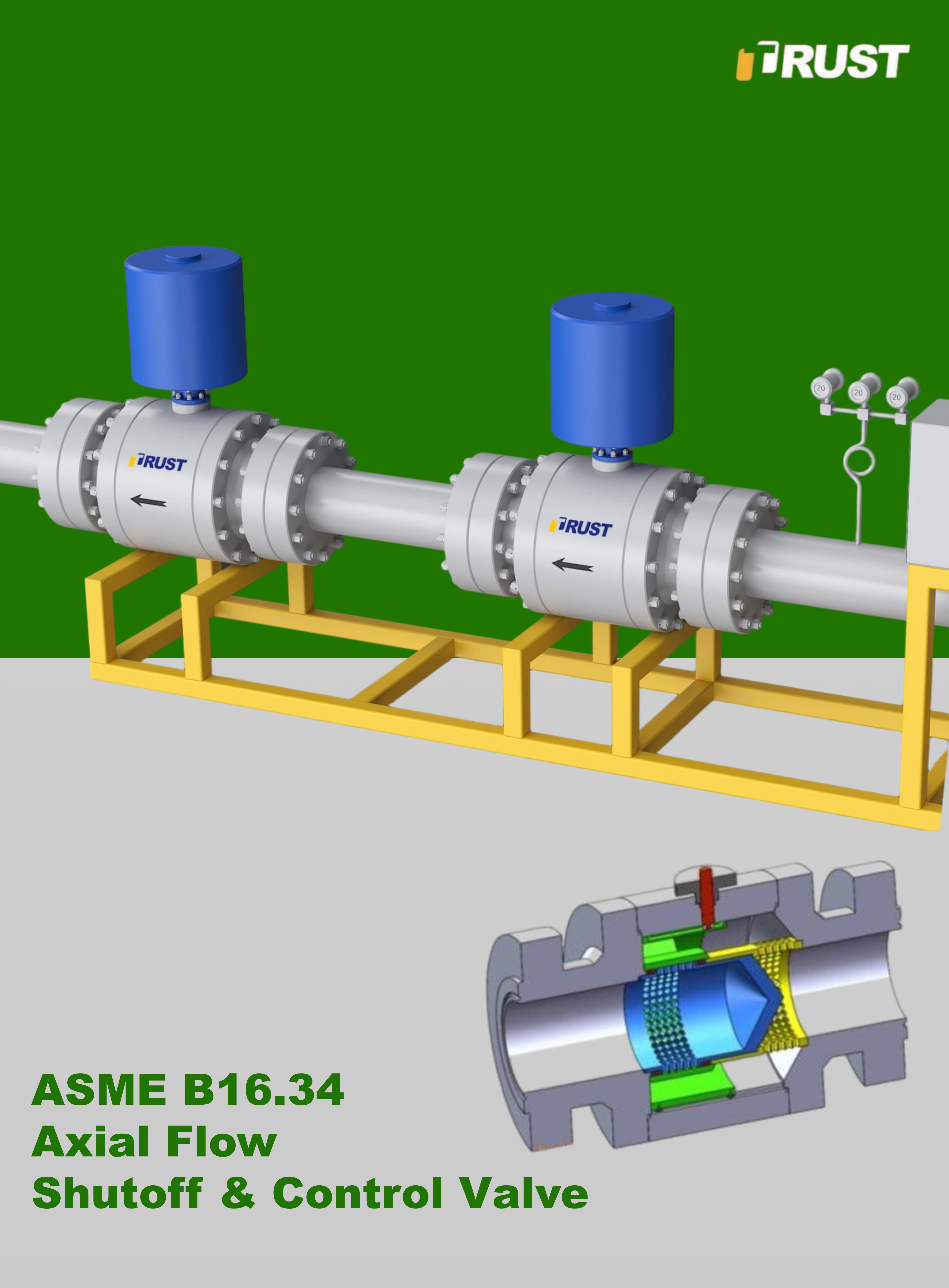

Our special alloy valve products are widely used in high-temperature, high-pressure, corrosive, and cryogenic conditions. We offer a full range of valve types, including gate valves, globe valves, check valves, ball valves, gauge valves, gauge valve clusters, and pigging valves. We also provide customized valve solutions tailored to specific needs. Whether you require valves for the oil, gas, chemical, or marine energy industries, our valves are designed to effectively handle complex operational conditions and ensure system safety.

The following table provides a brief overview of our main products and their application fields:

| Valve Type |

Application Fields |

Features and Advantages |

| Gate Valves |

Oil, gas, power generation |

Excellent sealing, high temperature and pressure resistance, ideal for large flow control |

| Globe Valves |

Chemical, petrochemical industries |

Precise flow control, suitable for applications requiring accurate regulation |

| Check Valves |

Petrochemical, natural gas pipelines |

Prevents backflow, ensures safe operation of equipment |

| Ball Valves |

Oil, gas, power generation |

Reliable sealing, low flow resistance, ideal for quick flow control |

| Pigging Valves |

Oil, natural gas pipelines |

Pigging function, ensures pipeline flow and prevents blockages |

In terms of technology, our company is equipped with complete inspection facilities to conduct NDT (RT, UT, MT, PT), cryogenic testing, and fire-safe testing as required. Moreover, our production process is managed by an ERP system, ensuring high consistency in production efficiency and quality.

Through continuous innovation and optimization, Trust Valve (Jiangsu) Co., Ltd. remains committed to meeting customer needs by offering high-quality, customized special alloy valve solutions. Our team not only has profound expertise and technical knowledge but also provides timely after-sales support to ensure our products perform optimally throughout their lifecycle.

English

English русский

русский Français

Français 中文简体

中文简体 Português

Português Español

Español italiano

italiano عربى

عربى فارسی

فارسی

cryogenicvalves.jpg)

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province

No.100 Xiejin Avenue, Funing County Economic Development Zone, Yancheng City, Jiangsu Province  +86-515-87398111

+86-515-87398111  office@trustvalve.com

office@trustvalve.com